Having crashed my bike a few times my fairing have had better days. I read up and realize it could be welded using a regular solder-iron.

The plastic i use for this are ABS-rods specifically made for ABS-welding, but if you have ABS filament for 3d printing, this will work as well.

The technique used is simple. Heat the area where you want to add material with a soldering iron and insert new material slowly building it up again. You can use a gas driven soldering iron, but only if it has a tip. Exposing ABS to a torch flame will ruin it in a heart-beat.

Start by cleaning up the piece, filing down dirt to expose clean material.

Cracked piece

Start by making a string in the direction you intend to build the plastic.

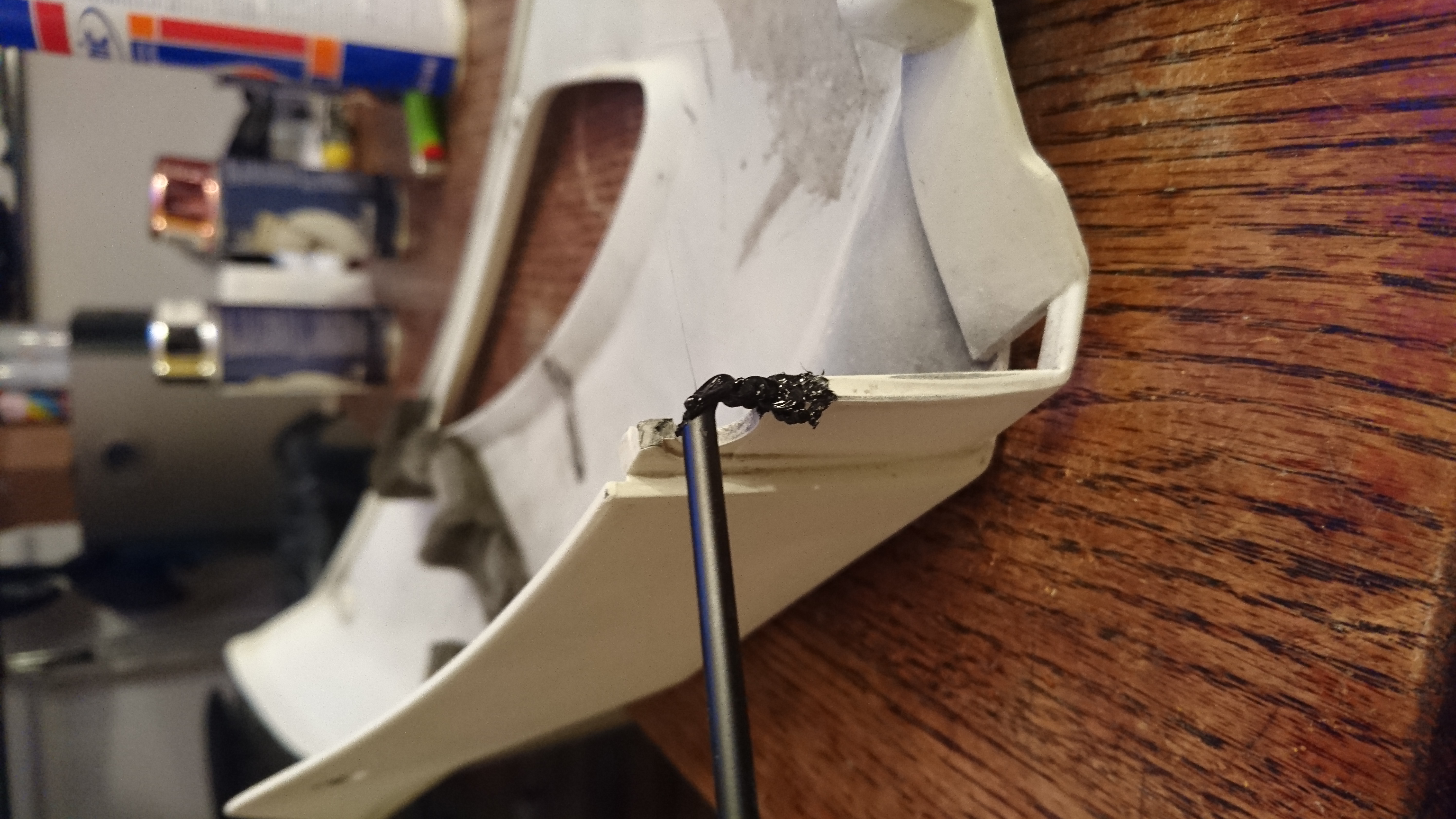

Starting to build up ABS

Continue injecting material, adding a good 2mm in thickness all around it. This will insure that the core of your new part becomes solid and that the piece is not full of tiny holes and gaps once filed down.

It’s important to inject a lot of material and avoid gaps with air.

Keep re-melting the plastic and insert more plastic to make sure it’s solid.

Redrilled and filed into shape.

After filing the piece down you might see small gaps. There is no harm in reheating and add more material if you see gaps.

A couple of coats of primer later

Only thing missing now is a few layers of paint and clearcoat and it will be as strong as new.

Your bike is now ready to be crashed again ;)